CASE

STUDIES

STUDIES

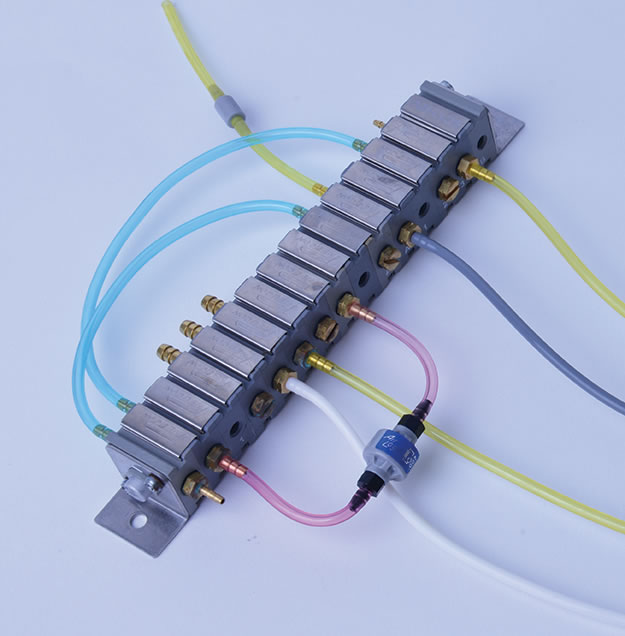

Automatic Subcutaneous Chick Vaccinator

Diamond Engineering’s highly successful Evolution IV Chick Vaccinator helps to protect poultry against contagious viral conditions such as Marek’s disease and Newcastle disease in countries the world over. Very early models of this device were manufactured by another company, prior to Diamond Engineering completing a successful acquisition in 1983.

The Problem

Early models of the vaccinator in use in South America were found to be susceptible to the climate. The ten pneumatic valves integral to these previous generation machines required servicing far more frequently than first envisaged, increasing downtime, labour and costs for an otherwise contented customer base.

The Solution

A dedicated Diamond Engineering R&D team quickly resolved the issue by reducing the number of valves in the vaccinator from ten to just two of a new type. Six months of field trials with the re-engineered model established that the replacement valves were maintenance-free and required no servicing at all. General service intervals were extended, and test machines were found to be still working optimally after 500 million cycles.

The Outcome

- The Evolution IV is now the most cost-effective and reliable chick vaccinator available.

- Re-engineering improvements have maximized operational uptime and minimized customer expenditure associated with servicing and maintenance, including the labour of trained service personnel.

- There is a reduced requirement for operators to hold costly spare parts in inventory.

- Greatly enhanced reliability is evidenced by the fact that today, after 500 million cycles, many of the new generation two-valve vaccinators first manufactured by Diamond Engineering are still working flawlessly.

Free Report

Sign up to receive your free report - How To Stop Stress From Late Deliveries and Rejects.

|

|

|

We are your sub-contract manufacturing partner, delivering complete systems to your specified destination.

We are your sub-contract manufacturing partner, delivering complete systems to your specified destination.

Full Service Manufacturing

VIEW SERVICE